How This Box Frame Trellis Was Made

Step 1: Planning

For this trellis, a 25’ long, 6’ high and 4’ wide A-Frame trellis was selected.

It’s best to try to reduce waste by combining 6’ and 4’ lengths or 5’ lengths since EMT comes in standard 10’ lengths. Any scrap can be used for additional bracing, and Maker Pipe 45 Degree Structural Connectors are great for that.

This guide includes affiliate links to tools and materials we personally recommend. If you purchase through them, we may earn a small commission at no extra cost to you.

Tools:

Materials:

17 x 10’ lengths of 3/4” EMT

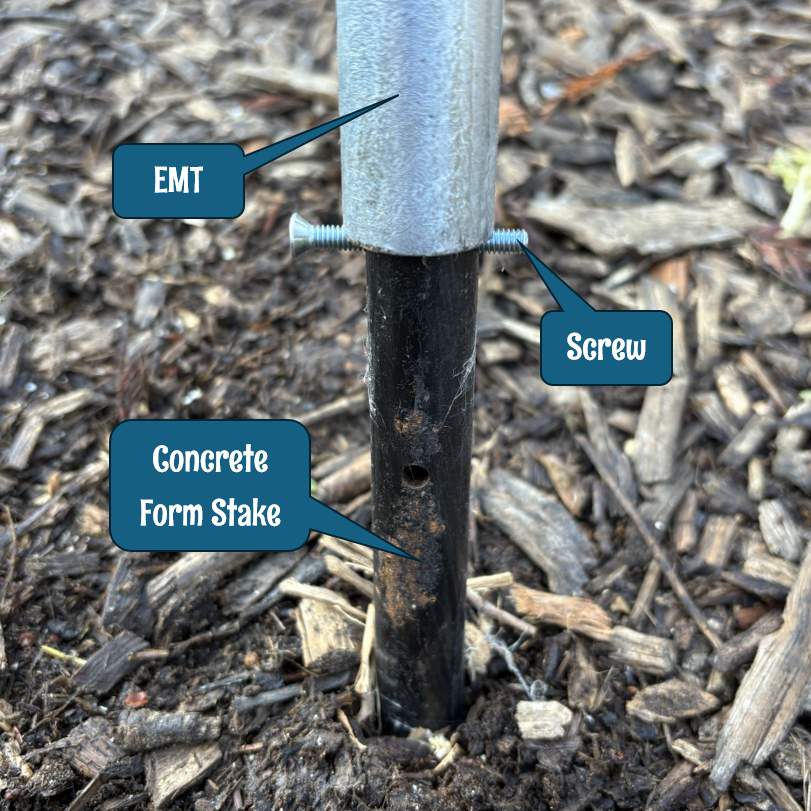

12 x Concrete Form Stakes

12 x Various Sized Screws

Step 2: Layout

Stakes were placed in the ground at the ends of trellis. A string line was tied between the stakes, creating a straight reference line.

Stakes were placed every 5’ along each of the string lines.

Step 3: Measure and Cut EMT

EMT sticks were measured and cut with a handheld tubing cutter.

Sticks 1–4: left full length, 10' (yields 4×10')

Sticks 5–10: cut 6' + 4' (yields 6×6' and 6×4')

Sticks 11–16: cut 6' (yields remaining 6×6' and leaves 4' scrap each)

Stick 17: cut 5' + 5' (yields 2×5')

Step 4: Slide EMT on Stakes

Screws were added into the stakes (see details and other options here).

6’ lengths of EMT were slid over the stakes.

EMT was leveled from the top with a hammer.

Step 5: Add the Horizontal EMTs and Fittings

The horizontal EMT lengths were added to the EMT legs with 90 Degree Structural Pipe Connectors. The connectors were placed loosely at first, then they were tightly secured with the hex tool once the trellis was leveled.

Horizontal EMTs were connected with Maker Pipe Structural Connectors.

Step 6: Ready for Action!

Now is when the fun begins! It’s time to start daydreaming about climbing plants and adding accessories.

In June 2025, this trellis was being used to support and shade tomato plants.